DENSO CORPORATION Using DataSpider Servista

Improving Development Productivity and Enhancing Governance by Minimizing the Impact on Each Country

Constructing a Data Integration Platform to Promote the Global Utilization of Data

DENSO CORPORATION, a global automotive parts manufacturer, began a project to re-construct their mission-critical business systems on a global scale, in order to enable smooth integration among the business sites that it has deployed in various countries around the world. As part of this project, the company examined a data accumulation and conversion service that would serve as a data integration platform. By using DataSpider Servista, they were able to successfully set up a platform that enables flexible linkage, with no need for users to be aware of the linkage destination.

Background

The company wanted to establish a data integration platform that could both utilize the production management mechanisms that had been individually constructed in each region, and also enable system construction that would be compatible with globalization.

Solution

The company decided to use DataSpider Servista, because it enabled linkage among various systems, both new and old, with a minimal burden, and also because they wanted to create an agentless environment.

Results

Utilized the data accumulation and conversion service

on a global scale

Improved productivity of

data-integration development and enhanced governance

Rich and advanced adaptors

enable even legacy mechanisms to be integrated

Background

The company needed a data integration platform in order to construct a global system

As a Tier 1 supplier that provides automotive parts directly to manufacturers, DENSO is expanding its business on a global scale. The company works with many systems that are essential for automobiles, and focuses both on automotive fields (such as electrification, advanced safety and automatic driving, and connected cars) and non-automotive fields (such as factory automation and the industrialization of agriculture).

With 211 consolidated subsidiaries in 35 countries and regions throughout the world, DENSO is making active efforts to globalize not only its management, but also its operations in the fields of human resources, research and development, and manufacturing. In the late 2000s, the company began a project to globally re-construct their mission-critical business systems for a variety of fields. In order to construct a system that was compatible with the globalization of business, they set up a team comprising members from throughout the organization, and made efforts to address a variety of issues.

Mr. Takeshi Nakayama

Mr. Takeshi NakayamaInformation Systems Div.

Project Assistant Manager

DENSO CORPORATION

One of the issues that came to light during this project was the need to establish a data integration platform to share, in a seamless fashion, information that had previously been handled individually in each region. Mr. Takeshi Nakayama, Project Assistant Manager at the Digital Work Promotion Department of the Information Systems Division, looks back on the project, saying: “For example, each region had its own production management mechanisms, and it was difficult to integrate all of them in an environment such as a cloud environment because they were all operating in a partially optimized state. Local operations were the reality. We needed to be able to integrate data from each region, while also utilizing our existing production management mechanisms.”

Introduction

DataSpider enables the introduction of a loosely coupled, agentless platform, with a minimal burden

DENSO wanted a loosely coupled mechanism that could flexibly integrate data without impacting the sending or receiving systems. In consideration of future scalability, they also wanted a mechanism that could achieve data integration with no need to install agents in each region’s environment. The goal was to create an environment where not only the existing environments, but also any new mechanisms that might arise in the future could be integrated.

Mr. Hidenori Fukui

Mr. Hidenori FukuiInformation Systems Div.

Project Assistant Manager

DENSO CORPORATION

Based on these needs, the company was drawn to DataSpider Servista (hereinafter, DataSpider), which is provided by Saison Information Systems. “At first,” says Mr. Nakayama, “we considered an ESB-type mechanism that would integrate applications via a bus. However, from the perspective of loose coupling, we decided that an EAI-type solution, which uses hub-and-spoke architecture to minimize the impact on the systems being integrated, would be ideal. Among the EAI solutions we considered, DataSpider provided rich and advanced adaptors, as well as exceptional cost performance.” The ease with which data integration could be performed was another factor in the selection of DataSpider. Mr. Hidenori Fukui, Project Assistant Manager at the Digital Work Promotion Department of the Information Systems Division, says, “DataSpider makes it possible to implement a variety of processing without writing code. All we need to do is arrange icons on the screen. Once we also took the improvement of development productivity into account, we determined that Data Spider was the optimum choice.” In an EAI solution, each region is not connected directly to the others in a full-mesh configuration. Instead, the EAI system acts as a hub to integrate the environments in a one-to-many configuration. However, new scripts must be incorporated every time a new integration-destination is added. DENSO was aware of these operational aspects from the planning and development stage, and highly praised DataSpider for the simple implementation it enabled.

HULFT, a file transfer tool provided by Saison Information Systems, has been used in Japan for over 20 years, and continues to be used today. DENSO also praised the product manufacturing of Saison Information Systems, which handles high-quality products that enable stable operations. As a result, they decided to use DataSpider for a data accumulation and conversion service to be used to flexibly integrate various regions.

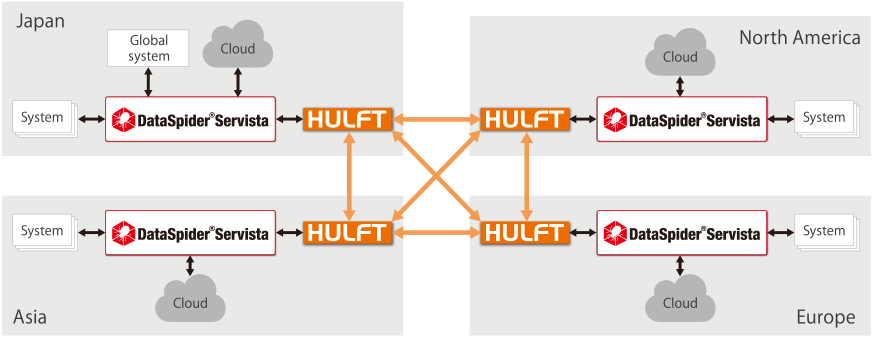

Configuration of a data accumulation and conversion service utilizing DataSpider and HULFT

Results

Achieving flexible data integration for each region, while also enhancing governance

Currently, the data accumulation and conversion service has been deployed throughout the world. The data accumulation and conversion servers used in Japan and in various regions in North America, Australia, and Asia are installed on an IaaS infrastructure, and data integration is achieved via an internal Group WAN. DataSpider is used, in combination with HULFT, for data integration within each region. The timing at which data integration is performed depends on the data’s purpose of use. For some data, once a day is sufficient. For other processes, such as accounting processes, however, data is exchanged as often as once every 30 minutes. The company is currently in the process of deploying data accumulation and conversion servers in China, and is considering future deployment to Europe.

As the result of using DataSpider, data integration is now possible with no need for the user to be aware of the integration-destination systems.

Mr. Hidenobu Yoshimura

Mr. Hidenobu YoshimuraSystem Management Dept.

Group Leader

DENSO IT SOLUTIONS, INC.

By providing development guidelines and integration templates, the company has succeeded in minimizing individual implementation, and has enabled flexible data integration with other regions. “While improving productivity related to data integration development, we have also been able to work toward enhancing governance,” says Mr. Hidenobu Yoshimura, Group Leader of the System Management Department of DENSO IT SOLUTIONS, INC. By involving the people in charge of operations in each region from the early planning stages, the company used a process that involved obtaining the understanding of the people involved regarding even those aspects of the operations that would change. As a result, the utilization of the system is proceeding smoothly in each region.

The company has also praised DataSpider for the wide range of adapters it provides (including adapters for legacy mechanisms such as Notes), which means that no internal mechanism is left behind, as well as for its powerful mapping functions that meet the various format-conversion needs of systems in a variety of fields. System construction, from planning to operational support, was carried out by NTT TechnoCross Corporation. “NTT TechnoCross selected DataSpider by looking at the situation from our point of view,” says Mr. Fukui. “They also provided thorough support for deployment outside Japan. We are grateful to them for responding to our difficult requests, and for making it possible to smoothly deploy the solution.”

Regarding the future of the project, Mr. Yoshimura says, “As a manufacturer, it is highly likely that we will need to become compatible with IoT and similar technologies going forward. We hope to continue our environment-building efforts with these issues also in mind.” Mr. Nakayama says, “By further expanding the data accumulation and conversion service we built by using DataSpider, and by promoting the global utilization of data, we hope to use this solution as a mechanism to demonstrate our synergy as a corporate group.”

User Profile: DENSO CORPORATION

As a global enterprise that provides automotive parts directly to manufacturers, DENSO CORPORATION has 211 consolidated subsidiaries in 35 countries and regions throughout the world. DENSO handles many systems that are indispensable for automobiles, such as thermal systems related to heat management, power train systems, electrification systems, and mobility systems. The company focuses both on automotive fields (such as electrification, advanced safety and automatic driving, and connected cars) and non-automotive fields (such as factory automation and the industrialization of agriculture).

Notes:

- HULFT and other products related to HULFT are registered trademarks or trademarks of Saison Information Systems Co., Ltd.

- The company names and product names mentioned in this document are trademarks or registered trademarks of their respective companies.

- Trademark symbols (TM, ®) might not be appended to the system names, product names, etc., mentioned in this document.