OMRON Corporation Using DataSpider Servista

Even in a global environment, differences in the systems used in each country can be flexibly absorbed by DataSpider Servista.

It can be also used as a data integration platform to support factory traceability system.

As a global leader in the field of automation, OMRON’s business fields cover a broad spectrum, ranging from industrial automation and electronic components to healthcare. As part of its efforts to identify the scope of the impact caused by failures and other problems at production base and to improve on-site work operations, the company is building a traceability system to visualize factory operating conditions. DataSpider Servista plays a pivotal role in OMRON's operations, efficiently converting information from various environments at each site, such as Excel and existing distributed systems, into an appropriate format and seamlessly linking the data with the upper-level traceability system.

Issue

OMRON wanted to build a traceability system to visualize information relevant to improving quality in factories.

Results

Established a

global traceability system

for factories, including partner companies

DataSpider Servista provided

flexible integration

even in different environments at different bases

Visualization of the bases was

also applied for on-site improvement activities and feedback to development team

Background

Developing a traceability system was urgently needed to grasp the incident situation quickly.

Mr. Toshitaka Nishimoto

Mr. Toshitaka Nishimoto Assistant Manager

Quality Planning Dept.

Quality Management Division

Device & Module Solutions Company

OMRON Corporation

OMRON has created social needs to realize a better society under its corporate mission: "To improve lives and contribute a better society." The Devices & Module Solutions Company (DMS) handles OMRON's founding business of electronic components. The company deals with electronic components for various industries, such as electric mobility, eSports, the energy industry, and semiconductor inspection equipment. It operates not only its production base but also those of its partners outside the OMRON Group worldwide.

OMRON's electronic components are mainly produced using automated assembly machines that mass-produce thousands of units per hour in fully automated units, so if a problem occurs, it will affect many customers. Mr. Toshitaka Nishimoto, Assistant Manager in Quality Planning Department of Quality Control Division, explains the importance of a traceability environment. He explains, "Therefore, to minimize damage, we needed to develop a traceability environment where on-site information is collected and fed back, enabling us to address any defects immediately." In addition, although the company had been operating a system to record information from the site, it was mainly on paper or Excel. Mr. Koichi Watanabe, Assistant Manager of Quality Planning Department explains, "It's much work just for experienced team members to formulate a hypothesis, find the data, and analyze it. And if the factory was overseas, we needed much more time just to collect the data."

Introduction

DataSpider Servista enables flexible data integration even in individually optimized environments for each site.

When designing the traceability system, it was crucial to thoroughly understand the points of change in procured materials, development processes, staff, equipment, and other factors that could potentially lead to defects. OMRON worked out the system requirements based on a packaged traceability system serving as the core. However, the environment at more than 50 bases, including overseas bases and partner companies, differed significantly, as the bases where the data originated had different tools, such as Excel and Access, in which they specialized. Looking back on those days, Mr. Nishimoto says, "At first, we considered installing iPads on the line to promote standardization, yet each base has its unique management methods, and standardized tools with the latest terminals were not necessarily required."

Mr. Koichi Watanabe

Mr. Koichi WatanabeAssistant Manager

Quality Planning Dept.

Quality Management Division

Device & Module Solutions Company

OMRON Corporation

DataSpider Servista, a data integration platform, drew attention as a means of smoothly collecting information from the base. As Mr. Watanabe explains, "We thought that even if we were operating on paper, we could at least get staff to input data into Excel, and an ETL solution with an Excel adapter would allow us to automatically collect data by attaching it to an email. "DataSpider Servista uses a GUI to create the data integration flow. The processes required for conversion and processing, as well as data input and output, can be achieved by dragging and dropping icons, so it was judged to be the most suitable environment for in-house production. Mr. Watanabe also states, "We thought that if we created the base of the data integration flow and developed it in such a way that it could be used by only making some changes when deploying it horizontally to each base, it would be fully utilizable even when it was produced in-house."

Results

DataSpider Servista provides powerful support for traceability systems to help control factory quality.

Currently, the system has been deployed in Kumamoto, Tottori and Okayama in Japan, and Shanghai and Shenzhen in China for overseas bases. For Malaysia and Indonesia, they are planning to migrate from an initial operation with Excel to a distributed system. Depending on the environment and scale of the factory, information is collected in various ways, including input on iPads, Excel, and existing distributed systems built individually. Data will eventually be collected from more than 50 bases.

Beyond traceability, they use the collected data in various ways. According to Mr. Nishimoto, "Initially, the information was collected as tracing information when something happened, but over the past few years the quality of work at the base has improved greatly and major problems no longer occur." Now, the purpose has changed to on-site improvement activities and feedback to development team."

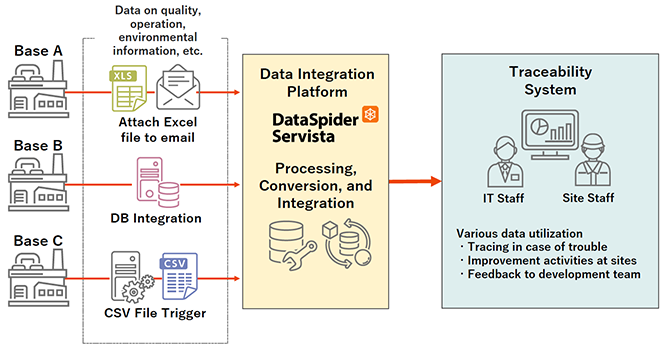

The information mainly obtained from the site is the part numbers of production orders from the production management system, various quality-related information, equipment measurements, and inspection record information. "In some cases, not only Excel is attached to emails, but CSV files extracted from distributed systems are automatically collected and linked by file triggers. If it is a partner company, there is a time lag to collect information from Excel attached to an email, but DataSpider Servista helps us to link these points together," Mr. Watanabe evaluates.

Images of Data Integration

In actual operation, various innovations have been devised to solve operational issues that arise on a case-by-case basis, such as DataSpider Servista's automatic processing of errors spit out from the DB, which are attached to an email and sent to the administrators. "If we had programmed in Java or VB, being flexible would have been challenging. Thanks to DataSpider Servista taking care of the integrating process, we can now maintain a stable environment for data integration," said Mr. Watanabe.

Next Stage

We want to further expand the range of partner companies and target devices to be acquired.

Currently, the traceability system is mainly deployed in Asia, including Japan and China, yet OMRON is also considering expanding the system in Europe including Italy.

Mr. Watanabe is enthusiastic: "We would like to actively pursue further expansion, such as responding to on-site needs by increasing the number of partner companies and expanding the range of equipment to be acquired."

User Profile: OMRON Corporation

- Headquarters

Shiokoji Horikawa, Shimogyo-ku, Kyoto, 600-8530, Japan - Business overview

As a global leader in the field of automation, OMRON’s business fields cover a broad spectrum, ranging from industrial automation and electronic components to social systems including automated ticket gates and solar power conditioners, healthcare. At present, OMRON provides products and services in more than 130 countries.

Notes:

- HULFT and other products related to HULFT are registered trademarks or trademarks of Saison Technology Co., Ltd.

- The company names and product names mentioned in this document are trademarks or registered trademarks of their respective companies.

- Trademark symbols (TM, ®) might not be appended to the system names, product names, etc., mentioned in this document.