CKD Using HULFT and HULFT-HUB

Using HULFT and HULFT-HUB for efficiently sharing data with overseas operations.

USER PROFILE

CKD manufactures and sells automatic machinery, pneumatic components, fluid control components, and other labor-saving devices globally.

Takahiro Doi,

General Manager,

Information Systems Division

Hiroyuki Nishimura,

Group Leader,

Systems Planning Group,

Information Systems Division

Problems

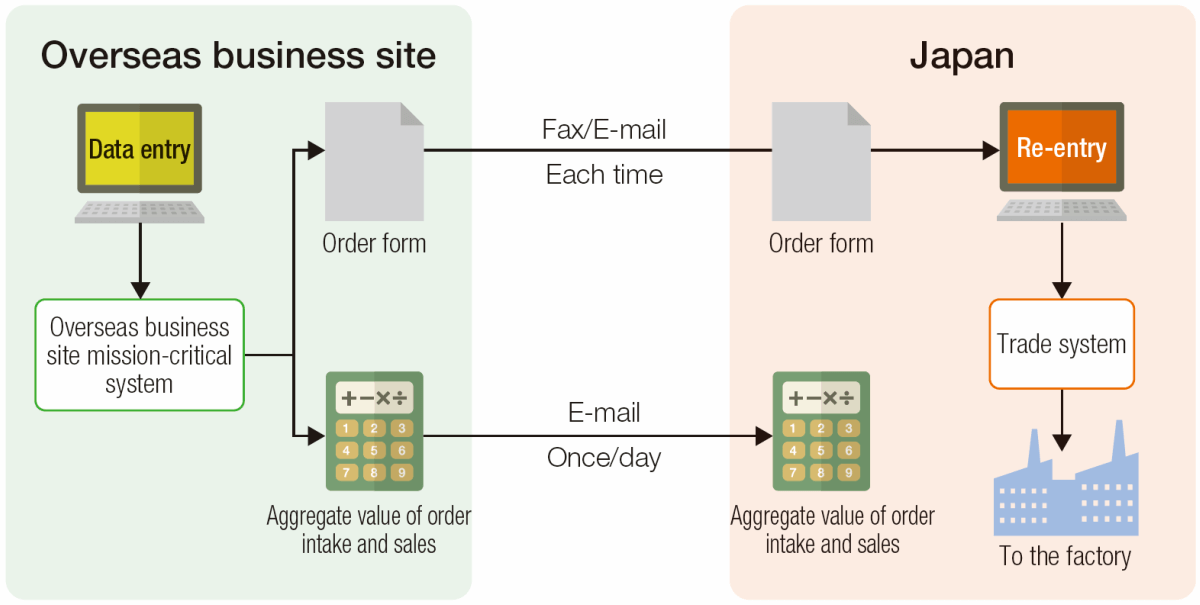

- Inefficiency: Since orders were being sent from overseas operations to the headquarters via email and fax, they had to be input to the system manually. It was both labor intensive and prone to human error.

- Delays: Since manual data entry took time, depending on the quantity of order forms received, communication to the factory was delayed, resulting in late deliveries.

- Management: At the smaller overseas operations, there was often nobody in charge of IT.

Solution

To improve the efficiency of back-end tasks and prevent erroneous entry, CKD built an information infrastructure linking its Japanese and overseas operations with HULFT and HULFT-HUB.

- Efficiency: Manual data entry was replaced with automation, saving time, labor, and cost. It also eliminated errors.

- Productivity: Staff who previously had to perform manual data entry were freed to focus on more productive tasks.

- Control: Using HULFT-HUB enabled centralized control by the Japanese headquarters.

- Reliability: In the case of poor network conditions, HULFT-HUB's data storage function and automation ensured the data transfers arrived as soon as possible.

- Synergy: The new setup enabled overseas bases to send orders to each other, expanding the capabilities of the entire group.