ASAHI INTECC CO., LTD. Using HULFT IoT

Creating an Environment where Data Can Be Retrieved Directly from IoT Devices

HULFT IoT EdgeStreaming Realizes the Visualization of the Manufacturing Process

ASAHI INTECC CO., LTD., a manufacturer of medical devices such as catheters and guide wires, introduced HULFT IoT for its ability to flexibly input and output in-formation after searching for an IoT environment solution suitable for their com-pany's manufacturing process. The EdgeStreaming function is used to collect in-formation smoothly from on-site PLCs (Programmable Logic Controllers) and send that information to a database in a reliable way, in order to realize the creation of an IoT environment for the effective visualization of the manufacturing process.

Issue

Creation of an environment where data can be used more effectively via digitization of the manufacturing site and advancements in IoT.

Solution

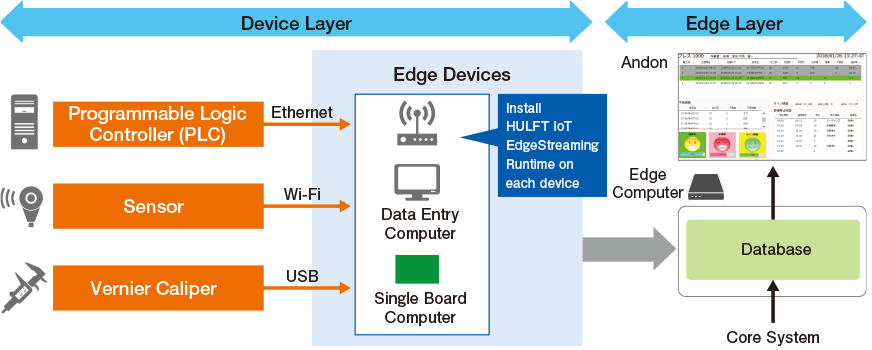

Introducing HULFT IoT provides a runtime module that can be installed on a variety of IoT devices, such as PLCs and single board computers, and enables writing of collected information directly to databases.

Result

Simplified On-Site Data Utilization

Reduced training cost

Resolved Discrepancies in Different Types of Communication Protocols

Simplified input and output of data

Realized Collection and Analysis of Raw Data

from Edge Devices

Background

Accelerating the Introduction of Industrial IoT as a Manufacturing Company

Catheter treatment is a minimally invasive medical procedure that aims to provide treatment while inflicting minimal harm on the body. The guide wires that are indispensable to this medical procedure are one of the main products manufactured by ASAHI INTECC, a development, manufacturing, and sales firm with a focus on medical devices. This global medical device manufacturer has already expanded its operations to 108 countries and regions worldwide. ASAHI INTECC has cultivated and developed the advanced technology of ultra-fine stainless wire rope for use in surgery since its founding. Taking advantage of this advanced technology, they have distinguished themselves from the competition with their integrated system for production from the raw materials to the product itself. ASAHI INTECC continues to produce products with high added-value for society, such as expansion of the techniques for treatment of CTO (Chronic Total Occlusion), which previously had no alternative treatment other than surgery, and other progressive investment in research development.

Industry 4.0 became a hot topic in the market around 2015, and a project was launched to promote the introduction of IoT as a manufacturing company. Mr. Kazutaka Yamada, Global Headquarters and R&D Center Manager, Processing Technique Division, recalls of that time: "We searched for solutions while building on actual results, by examining what kinds of IoT are suitable for our manufacturing process."

Mr. Yoshiharu Abe

Mr. Yoshiharu AbeGlobal Headquarters and R&D Center Manager

Processing Technology Development Section

ASAHI INTECC CO., LTD.

In addition, since the operations in on-site manufacturing up until then relied mainly on traditional paper information, one of their goals was to realize the visualization of on-site manufacturing using IoT, considering that digitizing evidence is required for the manufacturing process in the future. "First of all, we decided to create an environment with IoT for effective data utilization, not only by digitizing existing paper information, but also by adding new information that we hadn't been able to obtain before digitization," explains Mr. Yoshiharu Abe, Global Headquarters and R&D Center Manager, Processing Technology Development Section, Lean Promotion & Processing Technique Division. Then, they held hearings with the personnel on-site about the needs of visualization, and as a result, they started working on the visualization of the extrusion process involved in their resin manufacturing process.

Introduction

HULFT IoT Suitable for Creating a Platform Compatible with Both Cut-ting-Edge and 30-Year-Old Technologies

A flexible input-output environment was necessary to achieve the IoT platform that ASAHI INTECC desired. "There's equipment on-site that's still working after 20 to 30 years. We needed a platform that could collect information from that existing equipment, as well as incorporating the latest technology. Moreover, the output destination of information, such as production management databases and chronological databases used for AI, varies depending on the purposes. That's why above all we required flexibility in the input and output mechanism," explains Mr. Yamada. Although it was already possible to collect data from PLCs, because each device uses a specific protocol for communication, the platform needed to be versatile enough to resolve discrepancies in communication protocols.

Mr. Kazutaka Yamada

Mr. Kazutaka YamadaGlobal Headquarters and R&D Center Manager

Processing Technique Division

ASAHI INTECC CO., LTD.

In addition, in order to visualize and utilize collected data to make improvements on the spot, the company needed an environment where information could be collected only on the edge side. "Collecting all the information in the cloud will cost money. Detailed on-site data can be most effectively utilized to make improvements if the data is examined on-site while it is still fresh. We were envisioning a method for storing information hierarchically, where the edge, core system, or other com-ponents could be utilized as necessary," said Mr. Yamada.

Then, they happened to notice Saison Information Systems Co., Ltd. at an exhibition. "Even though we were still in the planning stage at that time, we found that they were offering a function that was close to what we were envisioning: the ability to create a data stream from IoT devices directly to databases," Mr. Yamada explained.

Moreover, Saison Information Systems seemed to share the same developmen-tally-focused mindset as ASAHI INTECC, offering a product optimized for the company to catch up to its current needs. As for the functional interface, the runtime module could be installed in various environments, from PLCs to single board computers. Mr. Yamada recognized that this was how the environments they were envisioning could actually become a reality. In addition to those benefits, the ability to perform edge development without needing to do any programming was a major plus when considering how to improve conditions on-site.

As a result, the company decided to apply EdgeStreaming function of HULFT IoT as the means for implementing the flexible information collection and secure transfer methods required for the company to achieve the industrial IoT framework.

Result

Realizing Data Collection from PLCs and Taking the First Step toward Industrial IoT

The industrial IoT aimed by ASAHI INTECC would raise awareness through on-site visualization and support approaches for improvement. Currently these methods are being deployed as a pilot line at their research facility in Shizuoka. As the company's future goals and plans become finalized, they will continue to verify what kinds of data to collect. "Even if data is acquired from PLCs but the correlation between the acquired parameters is not visible, a new sensor needs to be added. HULFT IoT makes it possible to add new devices and collect information more easily, without modifying the PLCs. That's how we were able to create an environment where we can collect information flexibly, depending on our goals," was the conclusion.

With the successful implementation of an IoT platform using HULFT IoT, Mr. Abe expects that on-site system analysis can be achieved on a daily basis, and it will be helpful for work improvement. "Until now, only the person performing analysis of inspection results could visualize the work quality, but now the results of each production lot can be shared with the whole work site, which we think is one of the major positive effects." Most recently, the company is in the process of standardizing the KPI for measuring the quality of on-site performance and hopes to make it so that all business sites can be evaluated based on the same criteria. He hopes to provide the management team with an intersectional understanding by using the KPI determined by the visualization of processes.

HULT IoT is regarded highly for providing the functions that meet the specifications of the company, such as the flexibility for being installed to many different systems, the convenience of being able to install the runtime module on edge devices, and its interface for building a system intuitively without programming. Saison Information Systems is also regarded highly for its approach to projects from the on-site perspectives.

In the future, the company plans to continue to build and refine its systems in Japan and accelerate the transfer of their manufacturing function by expanding devel-opment to overseas business sites including Vietnam. As new needs emerge, ASAHI INTECC hopes to continue discussions and search for solutions together, explained Mr. Yamada.

System Configuration Utilizing HULFT IoT

User Profile: ASAHI INTECC CO., LTD.

ASAHI INTECC CO., LTD. is a manufacturer focusing on medical devices, including the guide wires that are essential for catheter treatment. This global medical device manufacturer has already expanded its operations to 108 countries and regions worldwide. ASAHI INTECC has worked hard to develop a high-quality superfine steel wire rope for use in surgery with their technical expertise. From the raw materials to the product itself, this company has distinguished itself from the competition with its integrated production system. The company continues to produce high value-added products through progressive investment in research development.

Notes:

- HULFT and other products related to HULFT are registered trademarks or trademarks of Saison Information Systems Co., Ltd.

- The company names and product names mentioned in this document are trademarks or registered trademarks of their respective companies.

- Trademark symbols (TM, ®) might not be appended to the system names, product names, etc., mentioned in this document.